MIM process MIM process | |||

Metal injection moulding (MIM) is a new manufacturing technology which combines powder metallurgy and plastic moulding. It has outstanding advantages in mass manufacturing of small complex and precise metal parts. The following figure illustrates the MIM production process diagram:

| |||

MIM Process in pictures MIM Process in pictures | |||

1.Material Mixing | Equipment | Material & Parts | |

|  | ||

Feeding:To mix about 60% metal powder with 40% plastic binder | |||

| |  | ||

2.Injection |  |  | |

Injection molding:To put the mixing material into the injection machine and inject it into the mold to form the parts. | |||

|  | ||

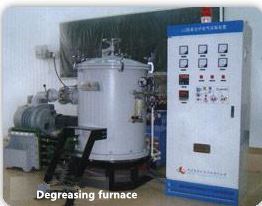

3.Degreasing |  |  | |

Degreasing: Using physical or chemical methods to remove the binder in the parts. The parts shrinkage occurs in volume, but shape and structure remain unchanged. | |||

|  | ||

4.Sintering |  |  | |

Sintering:This process is to densify parts. Further volume shrink happens, shape and structure unchanged. At this time the relative density is more than 95%. | |||